The apparel manufacturing industry is undergoing a significant transformation, driven by the rapid advancements in technology. From the design table to the factory floor, apparel manufacturing technology is revolutionizing how garments are conceived, created, and delivered to consumers.

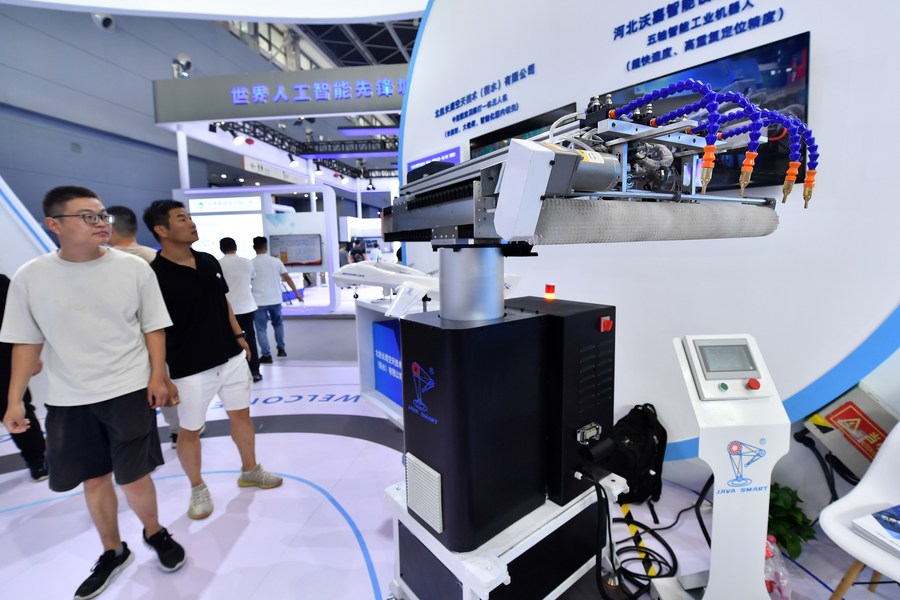

Automation and Robotics

One of the most prominent trends in apparel manufacturing technology is the increasing adoption of automation and robotics.

- Sewing Robots: Robots are increasingly being employed for repetitive tasks such as sewing, cutting, and assembling garments. These machines offer enhanced precision, speed, and consistency compared to manual labor, leading to improved quality and reduced production times.

- Automated Warehousing and Logistics: Automated guided vehicles (AGVs) and robotic arms are being used to streamline warehouse operations, improving efficiency and reducing labor costs.

- 3D Printing: 3D printing technology is gaining traction in the apparel industry, enabling the production of complex and customized garments with greater speed and flexibility.

Digitalization and Data-Driven Insights

Digital technologies are playing a crucial role in transforming the apparel manufacturing landscape.

- Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): CAD/CAM software allows designers to create and visualize designs digitally, while CAM software translates those designs into precise instructions for cutting and sewing machines.

- Product Lifecycle Management (PLM) Systems: PLM systems provide a centralized platform for managing the entire product lifecycle, from design and development to production and distribution. This enhances collaboration, improves efficiency, and reduces errors.

- Data Analytics: Data analytics is being used to analyze consumer trends, optimize production processes, and improve supply chain efficiency.

Sustainability and Circularity

Sustainability is a growing concern for consumers and brands alike. Apparel manufacturing technology is playing a crucial role in promoting more sustainable and circular production practices.

- Sustainable Materials: Technology is enabling the development and production of innovative sustainable materials, such as recycled polyester, organic cotton, and plant-based alternatives to leather.

- Waste Reduction: Technologies such as laser cutting and 3D printing can minimize fabric waste and reduce material consumption.

- Circular Economy Models: Apparel manufacturing technology is facilitating the development of circular economy models, where garments are designed for easy disassembly, repair, and recycling.

The Future of Apparel Manufacturing Technology

The future of apparel manufacturing technology holds immense potential.

- Artificial Intelligence (AI) and Machine Learning: AI and machine learning are poised to revolutionize the industry, enabling predictive maintenance, personalized product recommendations, and improved quality control.

- Virtual and Augmented Reality (VR/AR): VR/AR technologies are being used to create immersive design experiences, enhance customer engagement, and facilitate virtual try-ons.

- Blockchain Technology: Blockchain technology can be used to enhance supply chain transparency, improve traceability, and combat counterfeiting.

The continued advancement of apparel manufacturing technology will not only enhance efficiency and productivity but also drive innovation, sustainability, and greater consumer satisfaction. By embracing these technologies, the apparel industry can adapt to the evolving demands of the market and ensure its continued success in the years to come.