Industrial iot applications is revolutionizing various sectors by connecting industrial equipment and systems to the internet. This connectivity enables real-time data collection, analysis, and remote monitoring, leading to significant improvements in efficiency, productivity, and overall operations.

Predictive Maintenance

One of the most prominent industrial IoT applications is predictive maintenance. By continuously monitoring the performance of industrial equipment, IIoT solutions can identify potential issues before they escalate into costly breakdowns. Sensors embedded in machines can detect anomalies such as excessive vibration, temperature fluctuations, and pressure changes, allowing for timely maintenance interventions. This proactive approach minimizes downtime, reduces maintenance costs, and ensures 1 optimal equipment performance.

Remote Monitoring and Control

IIoT empowers remote monitoring and control of industrial processes. Operators can track key performance indicators (KPIs), such as production output, energy consumption, and quality parameters, from anywhere in the world. This real-time visibility enables timely adjustments to operational parameters, ensuring optimal resource utilization and minimizing waste. Furthermore, remote control capabilities allow for swift responses to unexpected events, such as equipment malfunctions or safety hazards, minimizing potential risks and ensuring business continuity.

Supply Chain Optimization

IIoT plays a crucial role in optimizing supply chains. By connecting various stakeholders, including suppliers, manufacturers, and distributors, IIoT solutions provide real-time visibility into the movement of goods. This visibility enables better inventory management, improved demand forecasting, and faster order fulfillment. Additionally, IIoT can help identify potential disruptions in the supply chain, such as delays or quality issues, allowing for proactive measures to mitigate their impact.

Smart Manufacturing

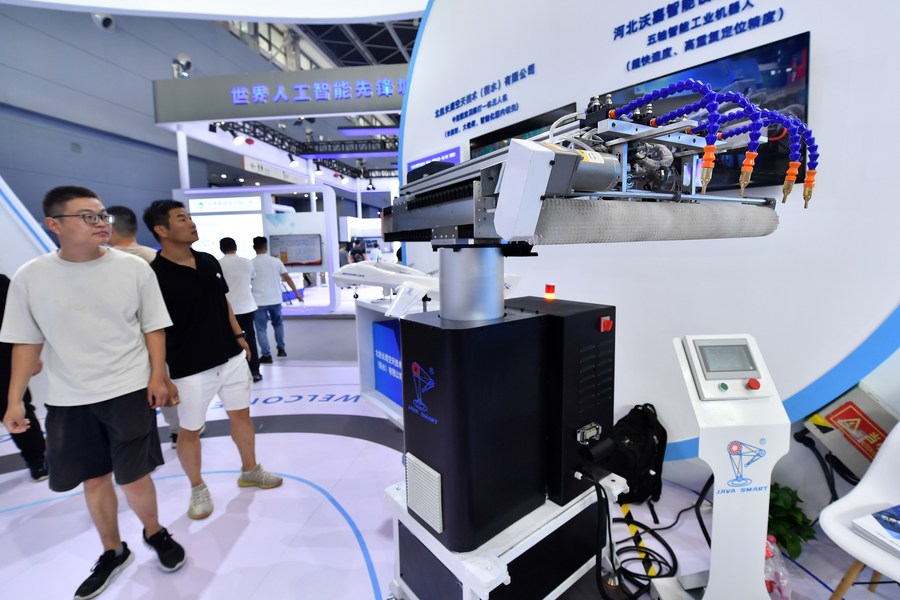

IIoT is driving the emergence of smart factories, where automation and data-driven decision-making are seamlessly integrated. By connecting machines, sensors, and software, IIoT enables real-time data exchange across the entire manufacturing process. This data-driven approach allows for continuous improvement of production processes, optimization of resource allocation, and enhanced quality control.

Energy Management

IIoT is instrumental in optimizing energy consumption across industrial facilities. By monitoring energy usage patterns and identifying areas of inefficiency, IIoT solutions can help reduce energy costs significantly. Smart meters, for instance, can provide real-time data on energy consumption, enabling operators to identify and address energy-intensive processes. Furthermore, IIoT can facilitate the integration of renewable energy sources, such as solar and wind power, into industrial operations, enhancing energy sustainability.

Safety and Security

IIoT plays a critical role in enhancing safety and security within industrial environments. By deploying sensors and cameras throughout the facility, IIoT solutions can monitor for potential hazards, such as gas leaks, fire outbreaks, and intrusions. Real-time alerts and notifications enable swift responses to emergencies, minimizing potential risks and safeguarding personnel and assets.

The Future of Industrial IoT Applications

Industrial IoT applications are constantly evolving, driven by advancements in technologies such as artificial intelligence (AI), machine learning (ML), and edge computing. AI and ML algorithms can analyze vast amounts of data generated by IIoT sensors, enabling predictive analytics and prescriptive maintenance. Edge computing, on the other hand, brings data processing closer to the source, reducing latency and improving real-time responsiveness.

As these technologies continue to mature, industrial IoT applications will become even more sophisticated and pervasive, transforming the way industries operate and unlocking new levels of efficiency, productivity, and sustainability.